SPECIFICATIONS

Brand Name: NoEnName_Null

Origin: Mainland China

Hign-concerned Chemical: None

Operating Speed: 24000 rpm

Certification: CE

Application: Milling

Brand: VEVOR

Rated Power: 2.2 KW

Voltage: 220V

Current: 6A

Frequency: 400 Hz

Collet: ER20

Collet Size (Dia.): 0.005" / 0.02" / 0.24" (0.125 mm / 0.5 mm / 6 mm)

Runout Off: 0.015 mm

Connection: ER20 diameter 0.125"-0.5" (3.175 mm-12.7 mm)

Bearing Model: 7005 x 1, 7002 x 2

Cooling: Air-cooled

Weight: 13.2 lbs / 6 kg

Item Dimensions: 4.33" x 11.69" (110 mm x 297 mm)

Current: 7.8A

-

Technical Parameters

-

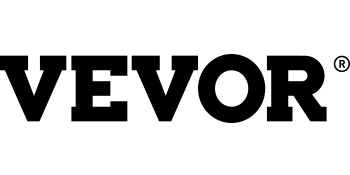

ER20 Standard Collet

-

Powerful Bearing

-

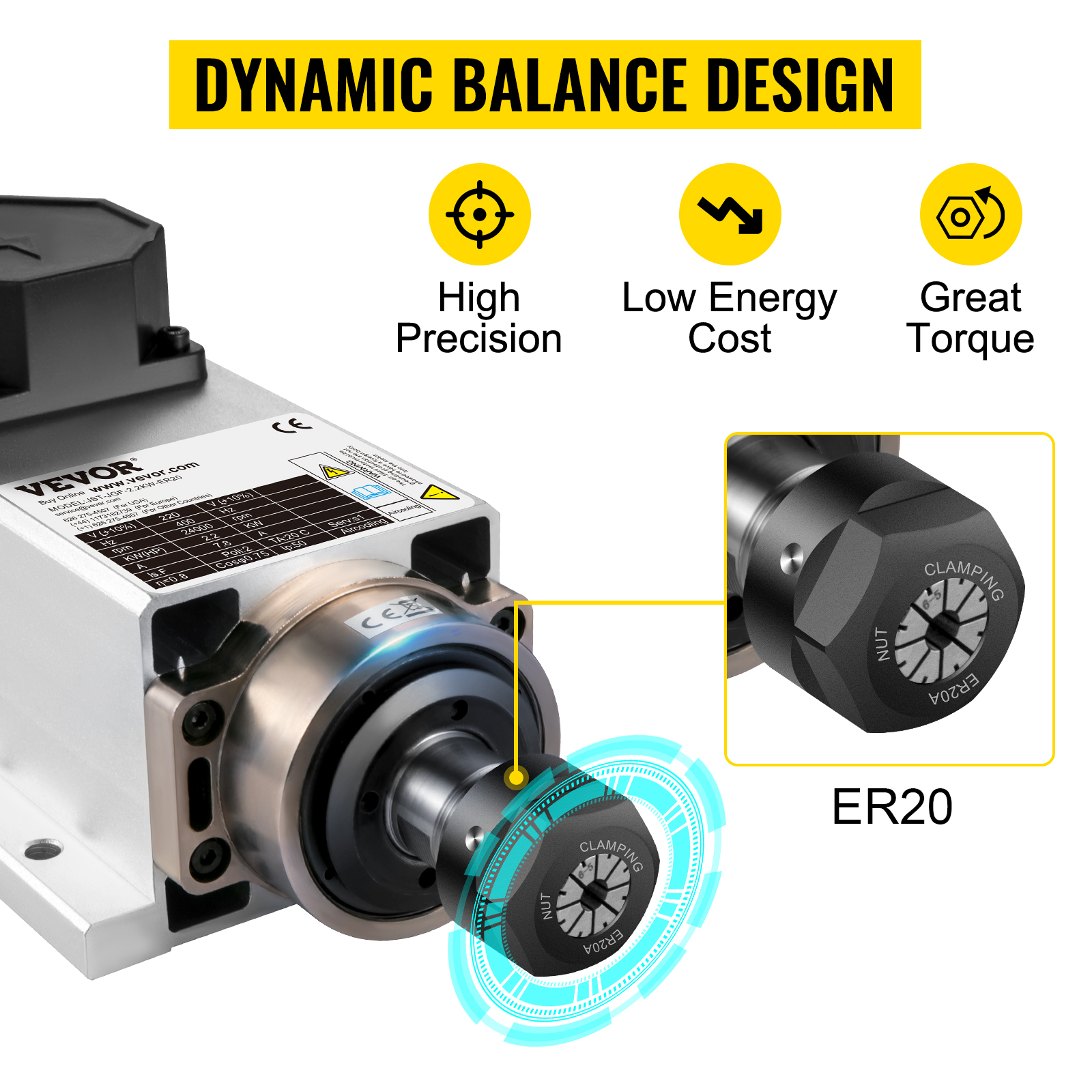

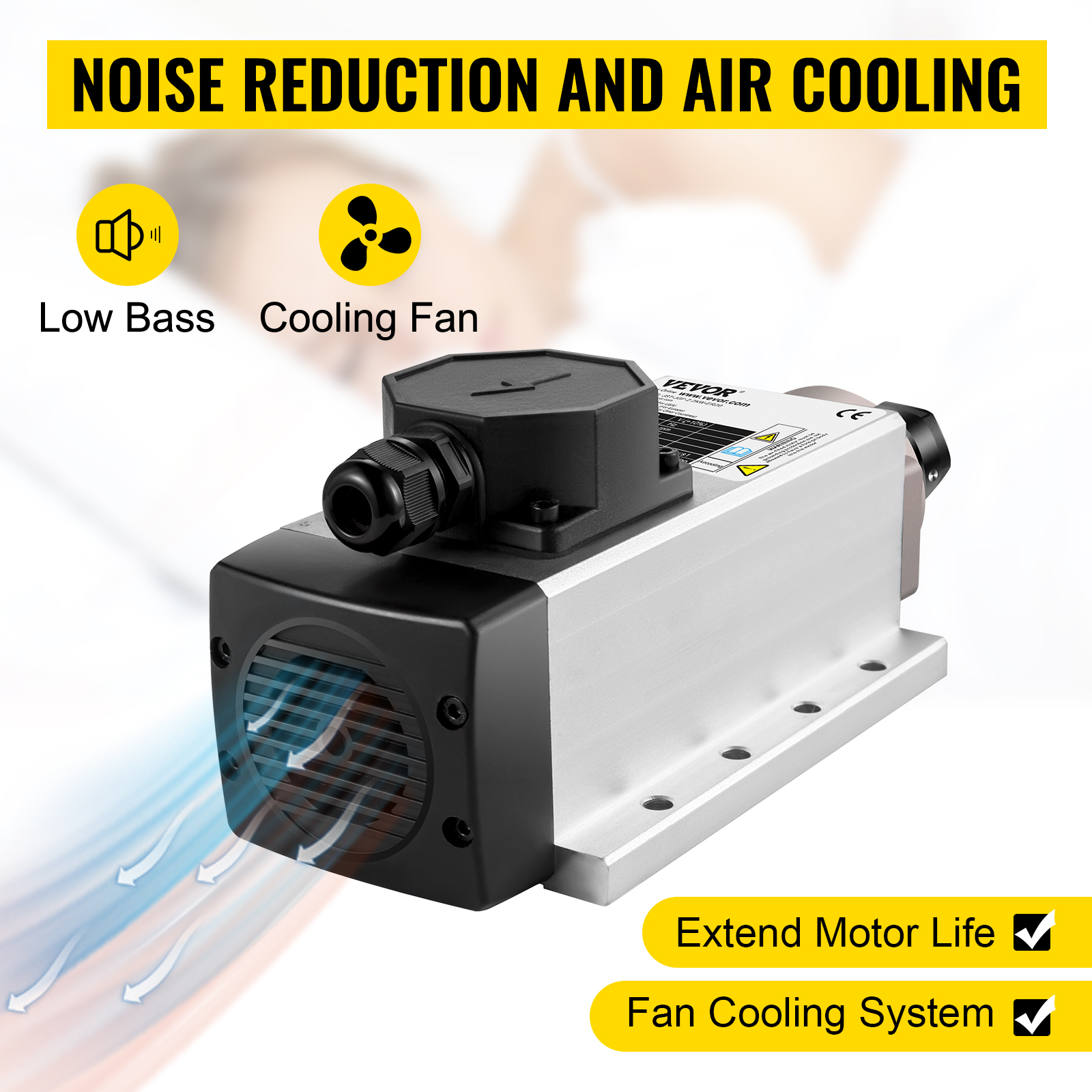

Low Noise & Heat Dissipation

employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly

low prices. Today, VEVOR's products are sold in more than 200 countries and regions with 10 million

plus members worldwide.

-

Premium Tough Quality

-

Incredibly Low Prices

-

Fast & Secure Delivery

-

30-Day Free Returns

-

24/7 Attentive Service

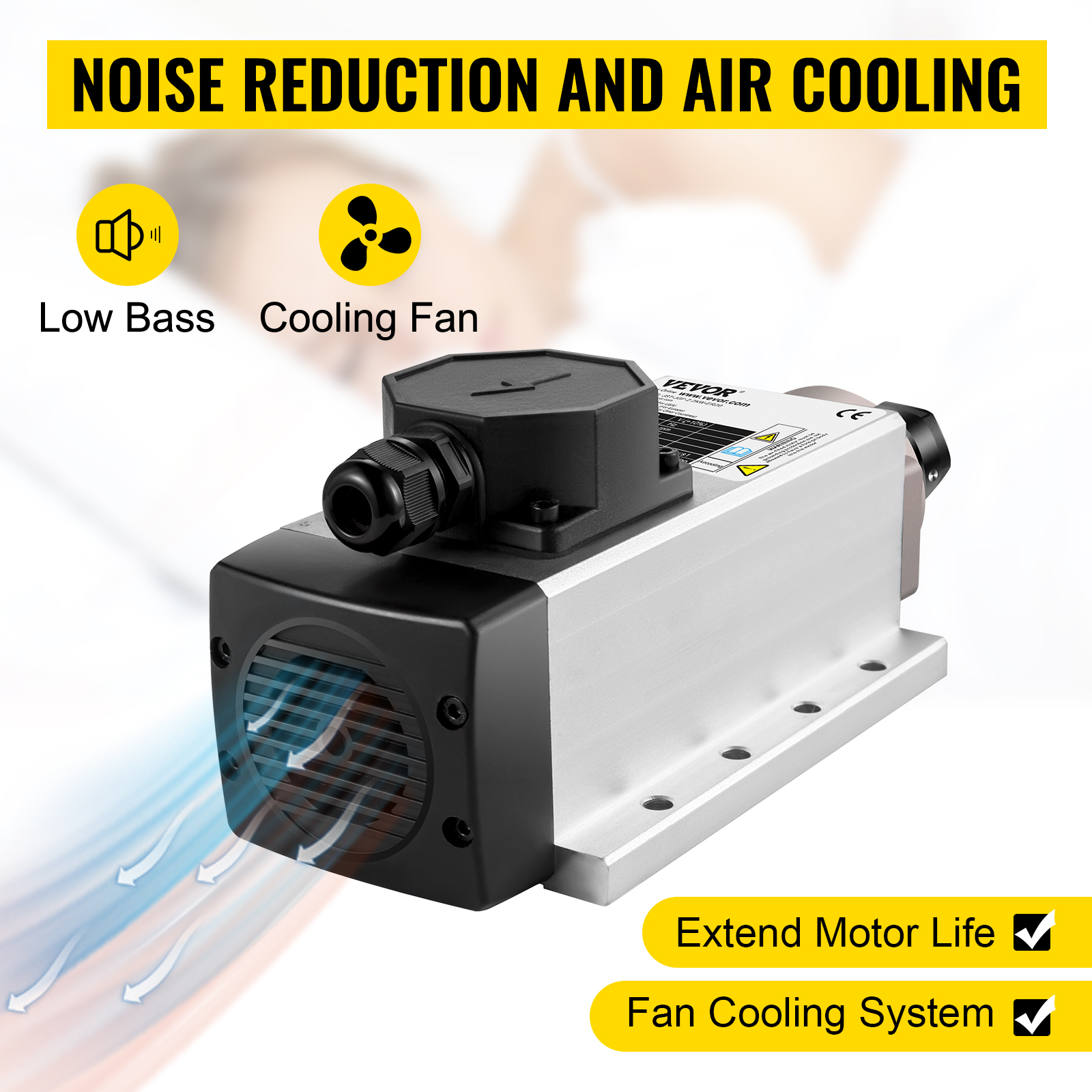

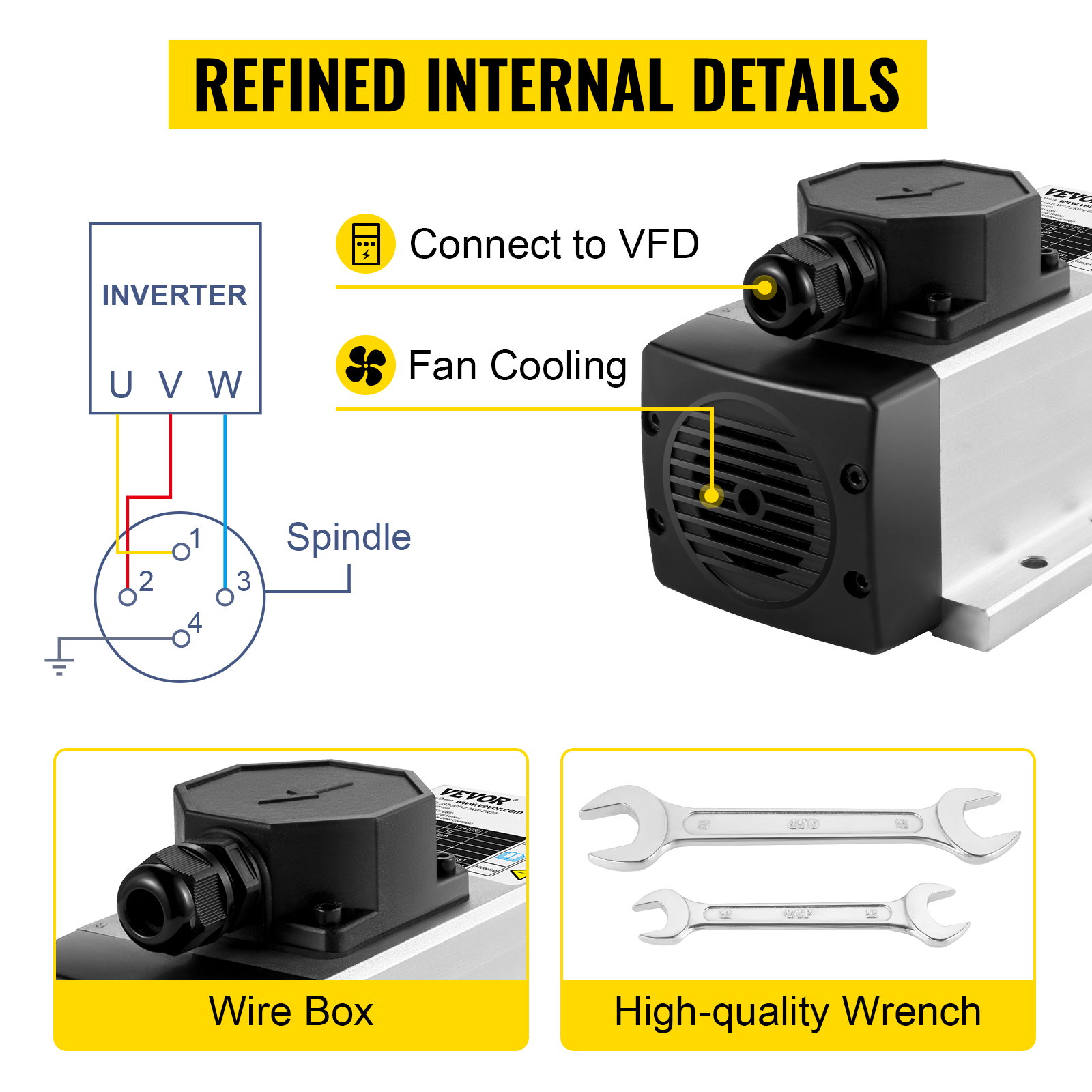

Instructions for use

1) In use, must first connect the cooling water pipe, make spindle connect cooling water and then start.

2) Before driving, turned by hand spindle. If sensory block is not flexible, you should troubleshoot, and then check the direction of rotation of the spindle from the spindle end to see if the match should rotate counterclockwise power wiring should be changed to make it consistent.

3) Before driving, cooling water for grinding workpiece can’t be in the front end of the spindle cover, to prevent the front bearing cover slot inlet burning motor and bearing. the motor must not enter the water, after turned on of the motor, when you live in grinding the workpiece to open the grinding of workpieces coolant. First off the workpiece coolant shutdown, and then close the spindle motor.

Maintenance and Service

1) Motorized spindle by medium frequency power supply rated voltage, frequency should be consistent with electric spindle technology parameters, motorized spindle rotational speed can change the frequency to adjust, also directly proportional voltage change.

2) When the spindle is temporarily not in use, should use compressed air to blow the coolant water,to avoid rusting, plug the hole. Spindle surface should be coated with anti rust oil. The shaft end protecting device, placed in dry place.

3) If replacement the spindle of bearings, best professional and technical personnel from the replacement. Use special tools, stator coil does not to be removed.

-

Power: 2.2 KW

-

Voltage: 220V

-

Frequency: 400 Hz

-

Speed: 24000 R/min

-

Runout off: Less than 0.002 mm

-

Collet Size (Dia.): 0.005" / 0.02" / 0.24" (0.125 mm / 0.5 mm / 6 mm)

-

Connection of Spindle End: ER20 ø 0.125"-0.5" (3.175 mm-12.7 mm)

-

Bearing Model: 7005 x 2, 7002 x 2

-

Maximum Torque: 1.2NM

-

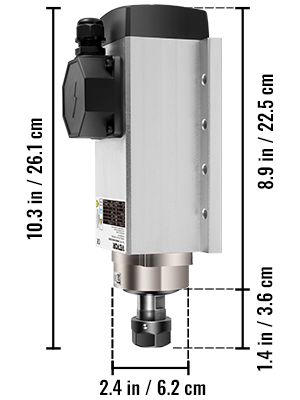

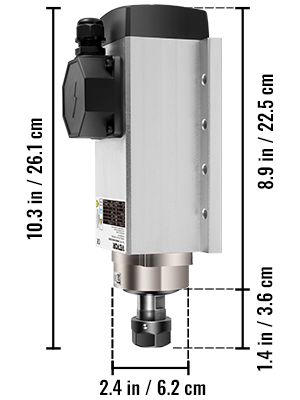

Product Dimension: 2.4 x 10.3 in / 6.2 x 26.1 cm

-

Weight: 13.2 lbs / 6 kg

-

Current: 7.8A

-

1 x Air Cooled Spindle Motor

-

2 x ER20 Collets

-

2 x Wrenches

-

Technical Parameters: Spec: φ2.4 x 10.3 in (Diameter: 6.2 cm x Length: 26.1 cm); Power: 2.2KW; Voltage: 220V; Current: 7.8A; Collet Size: ER20; Bearings: 4 bearings; Frequency: 400 Hz; Speed: 24000 R/min; Runout off: less than 0.002 mm. Mainly used for engraving machine or used with frequency converter.

-

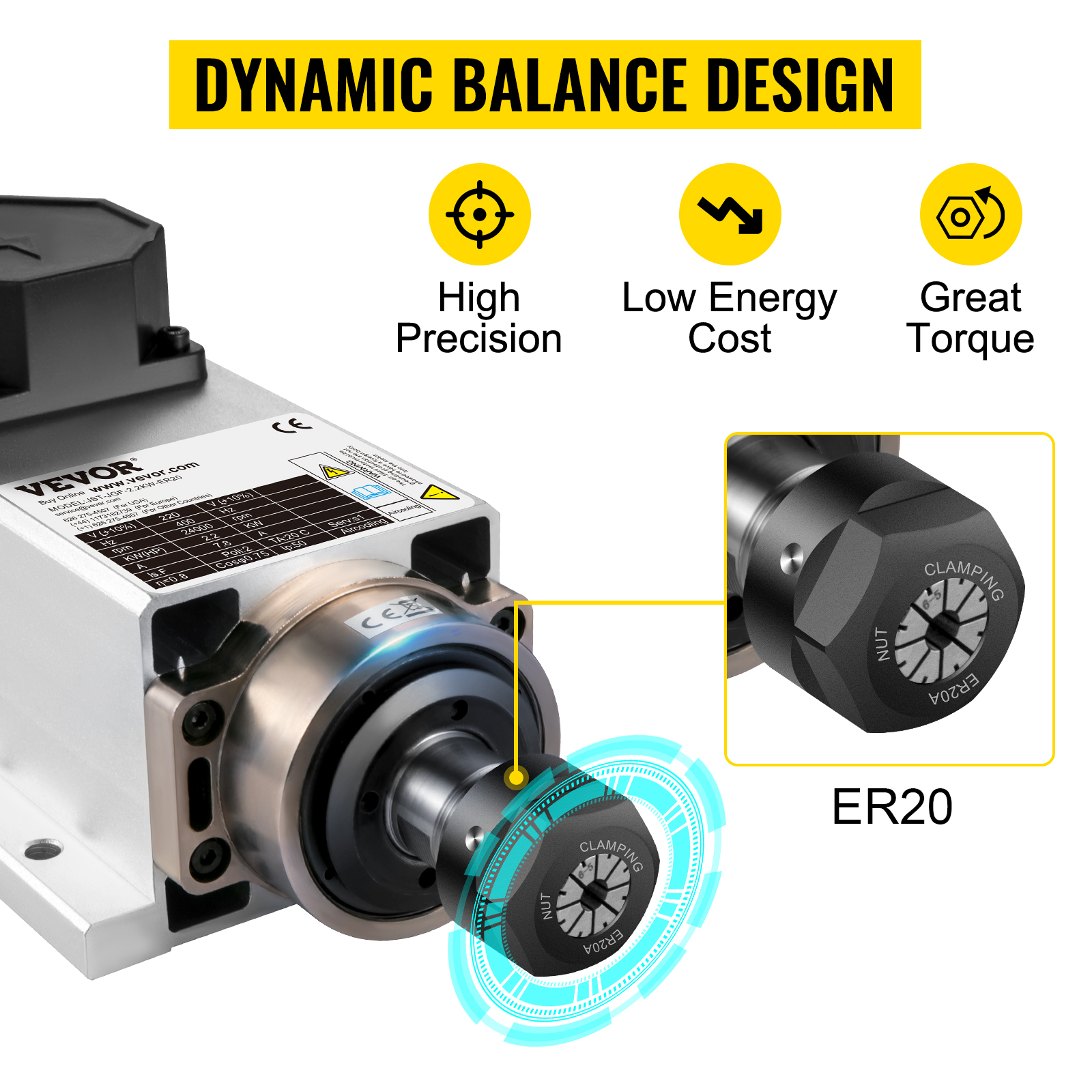

ER20 Standard Collet: The collet of the CNC router spindle is quenched with manganese steel, and the runout is less than 0.002 mm, which has high precision and is not easy to break the knife, increasing the stability of the working process. Dynamic balance technology can effectively reduce noise during use.

-

Powerful Bearing: The air spindle motor adopts imported bearings with high accuracy, precision, and durability. Significantly improve the hardness and anti-rust performance.

-

Low Noise & Heat Dissipation: The dynamic balance technology can effectively reduce the noise during use. The scientifically designed air cooling system has a better heat dissipation effect to ensure smooth operation.

-

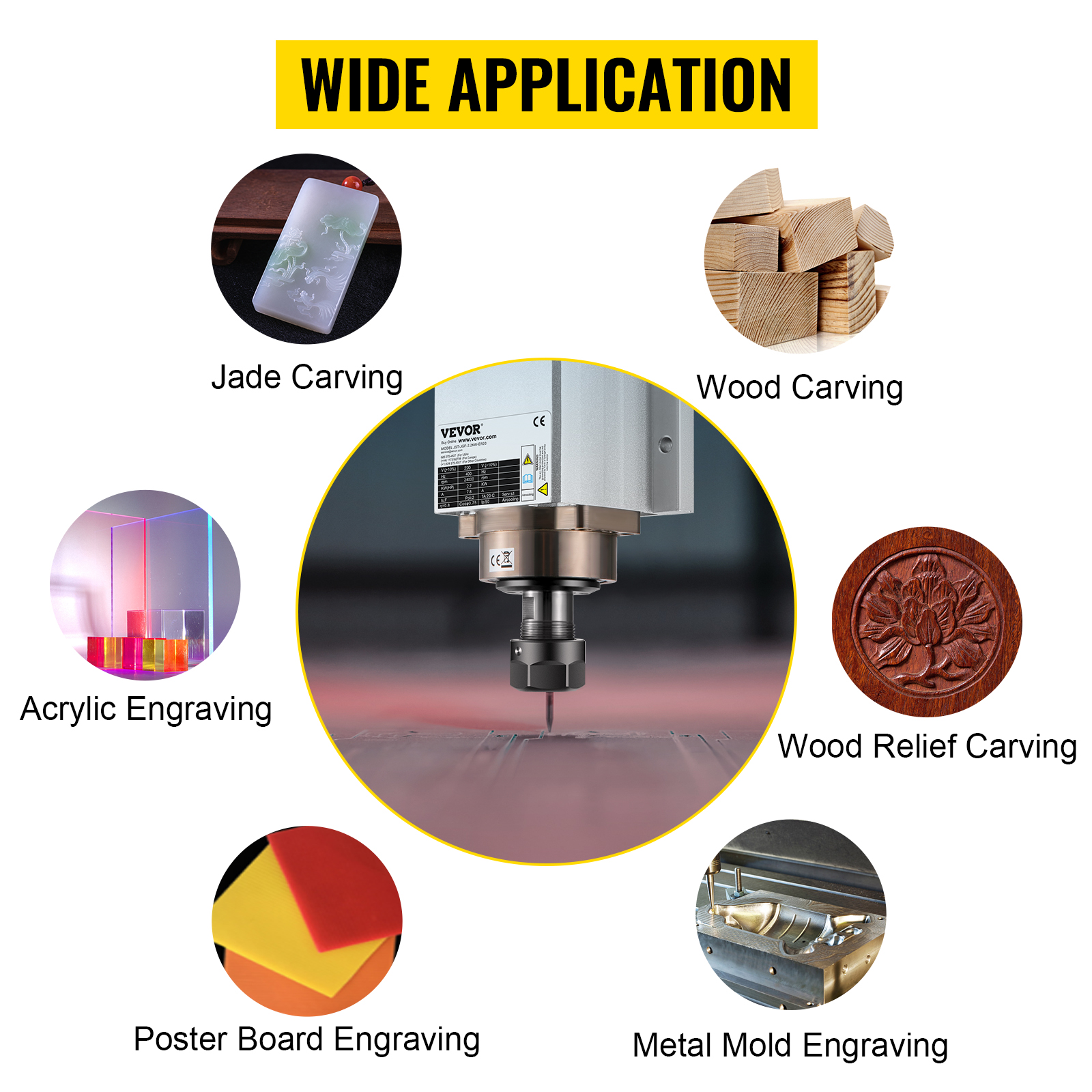

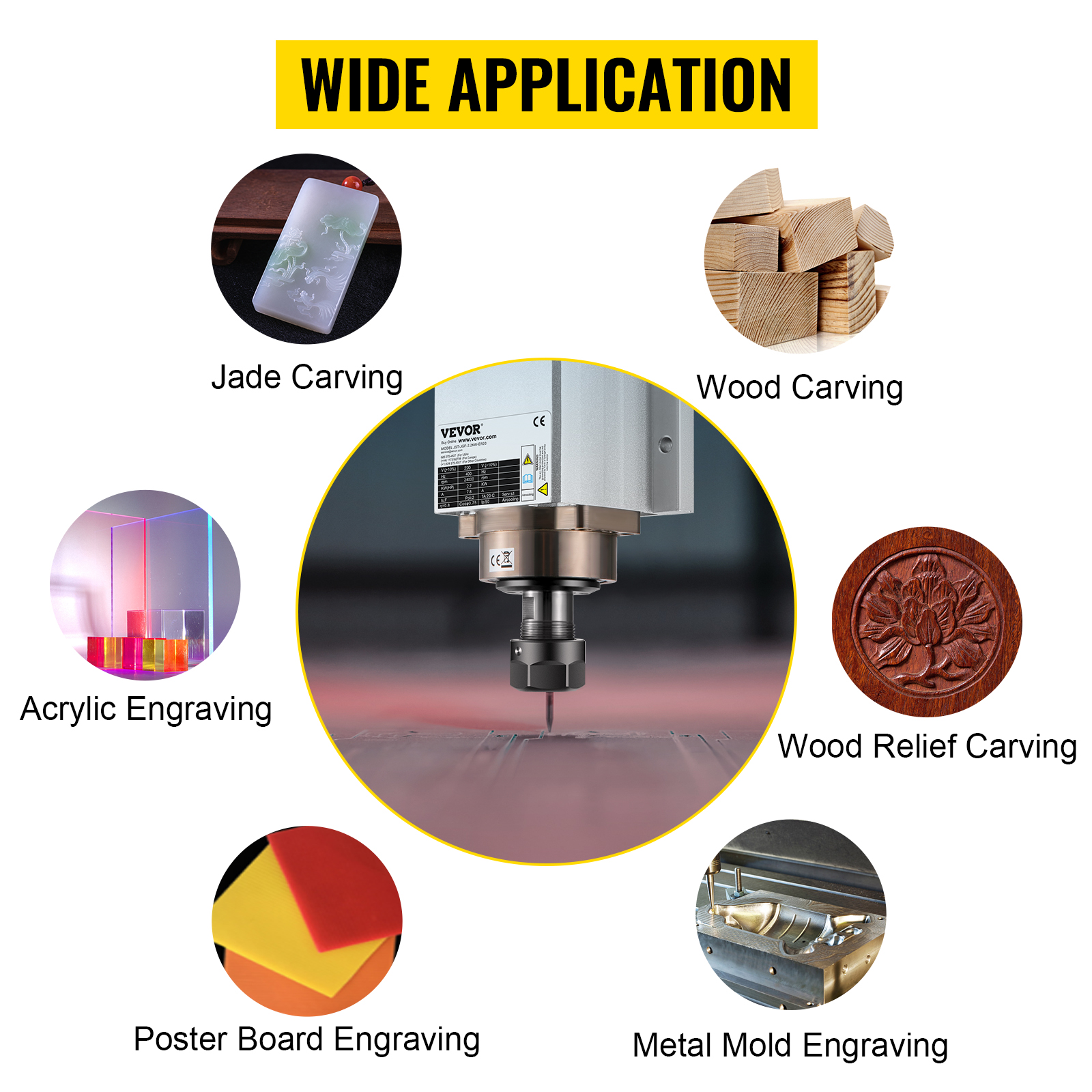

Wide Application: The CNC spindle motor kit is mainly used for engraving machines or frequency converters. It uses air circulation to cool the heat and has a good heat dissipation effect.

SPECIFICATIONS

Brand Name: NoEnName_Null

Origin: Mainland China

Hign-concerned Chemical: None

Operating Speed: 24000 rpm

Certification: CE

Application: Milling

Brand: VEVOR

Rated Power: 2.2 KW

Voltage: 220V

Current: 6A

Frequency: 400 Hz

Collet: ER20

Collet Size (Dia.): 0.005" / 0.02" / 0.24" (0.125 mm / 0.5 mm / 6 mm)

Runout Off: 0.015 mm

Connection: ER20 diameter 0.125"-0.5" (3.175 mm-12.7 mm)

Bearing Model: 7005 x 1, 7002 x 2

Cooling: Air-cooled

Weight: 13.2 lbs / 6 kg

Item Dimensions: 4.33" x 11.69" (110 mm x 297 mm)

Current: 7.8A

-

Technical Parameters

-

ER20 Standard Collet

-

Powerful Bearing

-

Low Noise & Heat Dissipation

employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly

low prices. Today, VEVOR's products are sold in more than 200 countries and regions with 10 million

plus members worldwide.

-

Premium Tough Quality

-

Incredibly Low Prices

-

Fast & Secure Delivery

-

30-Day Free Returns

-

24/7 Attentive Service

Instructions for use

1) In use, must first connect the cooling water pipe, make spindle connect cooling water and then start.

2) Before driving, turned by hand spindle. If sensory block is not flexible, you should troubleshoot, and then check the direction of rotation of the spindle from the spindle end to see if the match should rotate counterclockwise power wiring should be changed to make it consistent.

3) Before driving, cooling water for grinding workpiece can’t be in the front end of the spindle cover, to prevent the front bearing cover slot inlet burning motor and bearing. the motor must not enter the water, after turned on of the motor, when you live in grinding the workpiece to open the grinding of workpieces coolant. First off the workpiece coolant shutdown, and then close the spindle motor.

Maintenance and Service

1) Motorized spindle by medium frequency power supply rated voltage, frequency should be consistent with electric spindle technology parameters, motorized spindle rotational speed can change the frequency to adjust, also directly proportional voltage change.

2) When the spindle is temporarily not in use, should use compressed air to blow the coolant water,to avoid rusting, plug the hole. Spindle surface should be coated with anti rust oil. The shaft end protecting device, placed in dry place.

3) If replacement the spindle of bearings, best professional and technical personnel from the replacement. Use special tools, stator coil does not to be removed.

-

Power: 2.2 KW

-

Voltage: 220V

-

Frequency: 400 Hz

-

Speed: 24000 R/min

-

Runout off: Less than 0.002 mm

-

Collet Size (Dia.): 0.005" / 0.02" / 0.24" (0.125 mm / 0.5 mm / 6 mm)

-

Connection of Spindle End: ER20 ø 0.125"-0.5" (3.175 mm-12.7 mm)

-

Bearing Model: 7005 x 2, 7002 x 2

-

Maximum Torque: 1.2NM

-

Product Dimension: 2.4 x 10.3 in / 6.2 x 26.1 cm

-

Weight: 13.2 lbs / 6 kg

-

Current: 7.8A

-

1 x Air Cooled Spindle Motor

-

2 x ER20 Collets

-

2 x Wrenches

-

Technical Parameters: Spec: φ2.4 x 10.3 in (Diameter: 6.2 cm x Length: 26.1 cm); Power: 2.2KW; Voltage: 220V; Current: 7.8A; Collet Size: ER20; Bearings: 4 bearings; Frequency: 400 Hz; Speed: 24000 R/min; Runout off: less than 0.002 mm. Mainly used for engraving machine or used with frequency converter.

-

ER20 Standard Collet: The collet of the CNC router spindle is quenched with manganese steel, and the runout is less than 0.002 mm, which has high precision and is not easy to break the knife, increasing the stability of the working process. Dynamic balance technology can effectively reduce noise during use.

-

Powerful Bearing: The air spindle motor adopts imported bearings with high accuracy, precision, and durability. Significantly improve the hardness and anti-rust performance.

-

Low Noise & Heat Dissipation: The dynamic balance technology can effectively reduce the noise during use. The scientifically designed air cooling system has a better heat dissipation effect to ensure smooth operation.

-

Wide Application: The CNC spindle motor kit is mainly used for engraving machines or frequency converters. It uses air circulation to cool the heat and has a good heat dissipation effect.