SPECIFICATIONS

Brand Name: NoEnName_Null

Origin: Mainland China

Hign-concerned Chemical: None

Certification: CE

Spec(2.2KW): 80 x 215 mm (Diameter: 80 mm x Length: 215 mm)

Power: 2.2 KW

Frequency: 400 Hz

Speed: 0-24000 R/min

Collet Chuck: ER 20

Runout off: less than 0.005 mm

Length: 30 cm (12 Inches)

Width: 25 cm (10 Inches)

Height: 22 cm (9 Inches)

Gross weight: 5 KG(11.02 lbs)

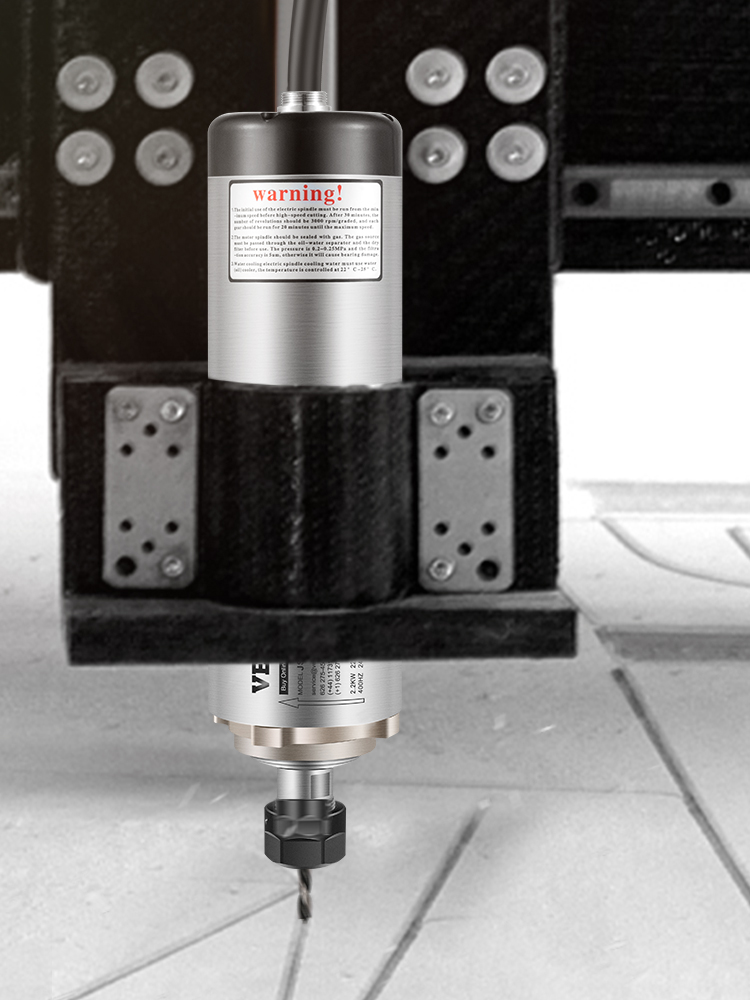

Product: Air Cooled Spindle Motor

-

Technical Parameters

-

ER20 Standard Collet

-

Powerful Bearing

-

Low Noise & Heat Dissipation

-

Premium Tough Quality

-

Incredibly Low Prices

-

Fast & Secure Delivery

-

30-Day Free Returns

-

24/7 Attentive Service

-

Power: 2.2 KW

-

Voltage: 220V

-

Frequency: 200-400 Hz

-

Speed: 12000-24000 R/min

-

Runout off: Less than 0.002 mm

-

Maximum Torque: 1.7NM

-

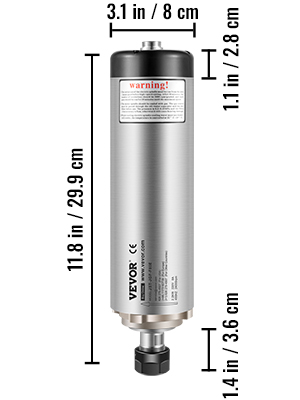

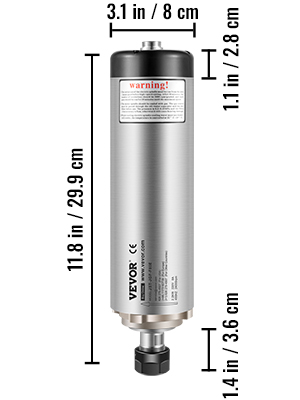

Product Dimension: 3.1 x 11.8 in / 8 x 29.9 cm

-

Weight: 13.2 lbs / 6 kg

-

1 x Air Cooled Spindle Motor

-

Technical Parameters: Spec: φ3.1 x 11.8 in (Diameter: 8 cm x Length: 29.9 cm); Power: 2.2KW; Voltage: 220V; Current: 8A; Collet Size: ER20; Bearings: 4 bearings; Frequency: 200-400 Hz; Speed: 12000-24000 R/min; Runout off: less than 0.002 mm. Mainly used for engraving machine or used with frequency converter.

-

ER20 Standard Collet: The collet of the CNC router spindle is quenched with manganese steel, and the runout is less than 0.002 mm, which has high precision and is not easy to break the knife, increasing the stability of the working process. Dynamic balance technology can effectively reduce noise during use.

-

Powerful Bearing: The air spindle motor adopts imported bearings with high accuracy, precision, and durability. Significantly improve the hardness and anti-rust performance.

-

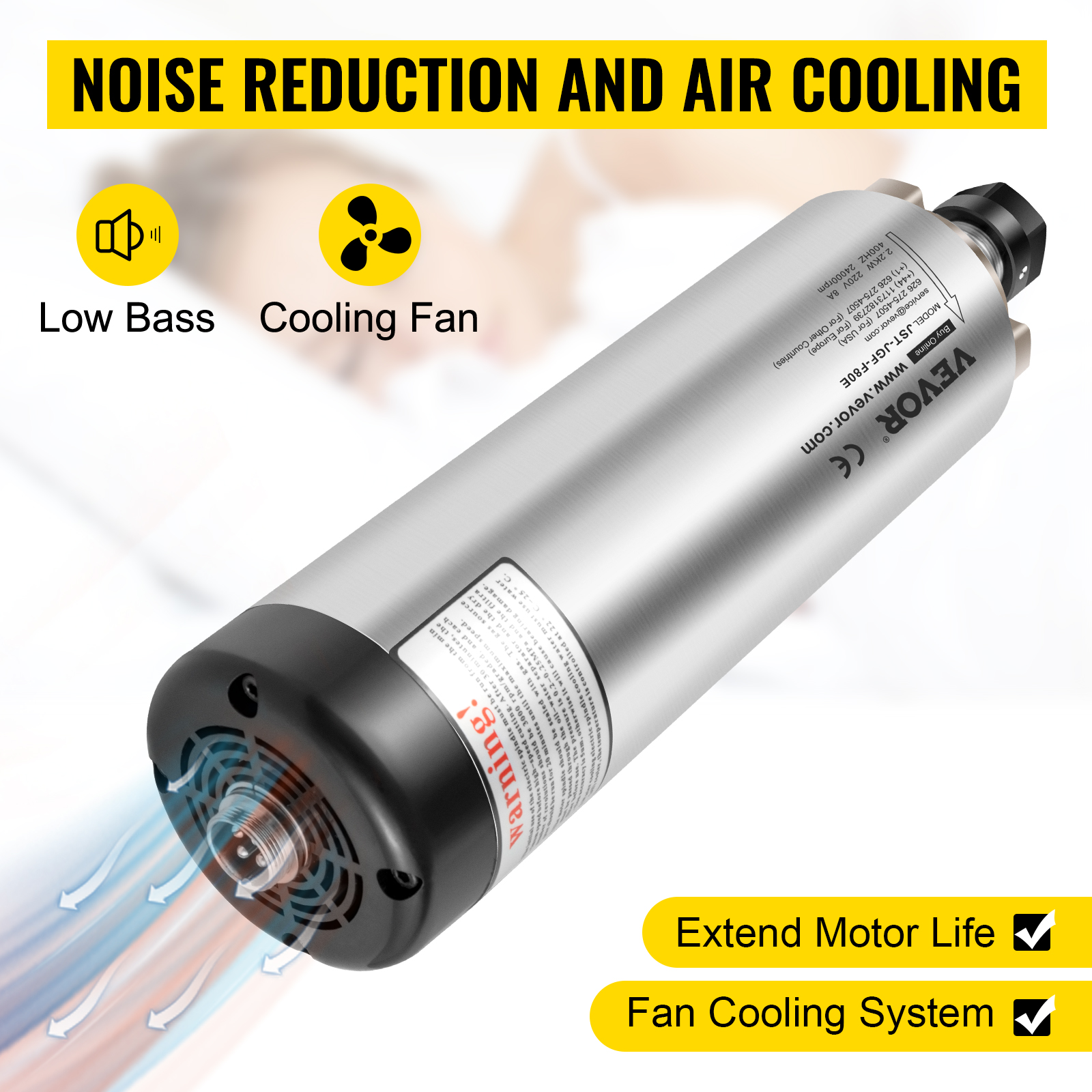

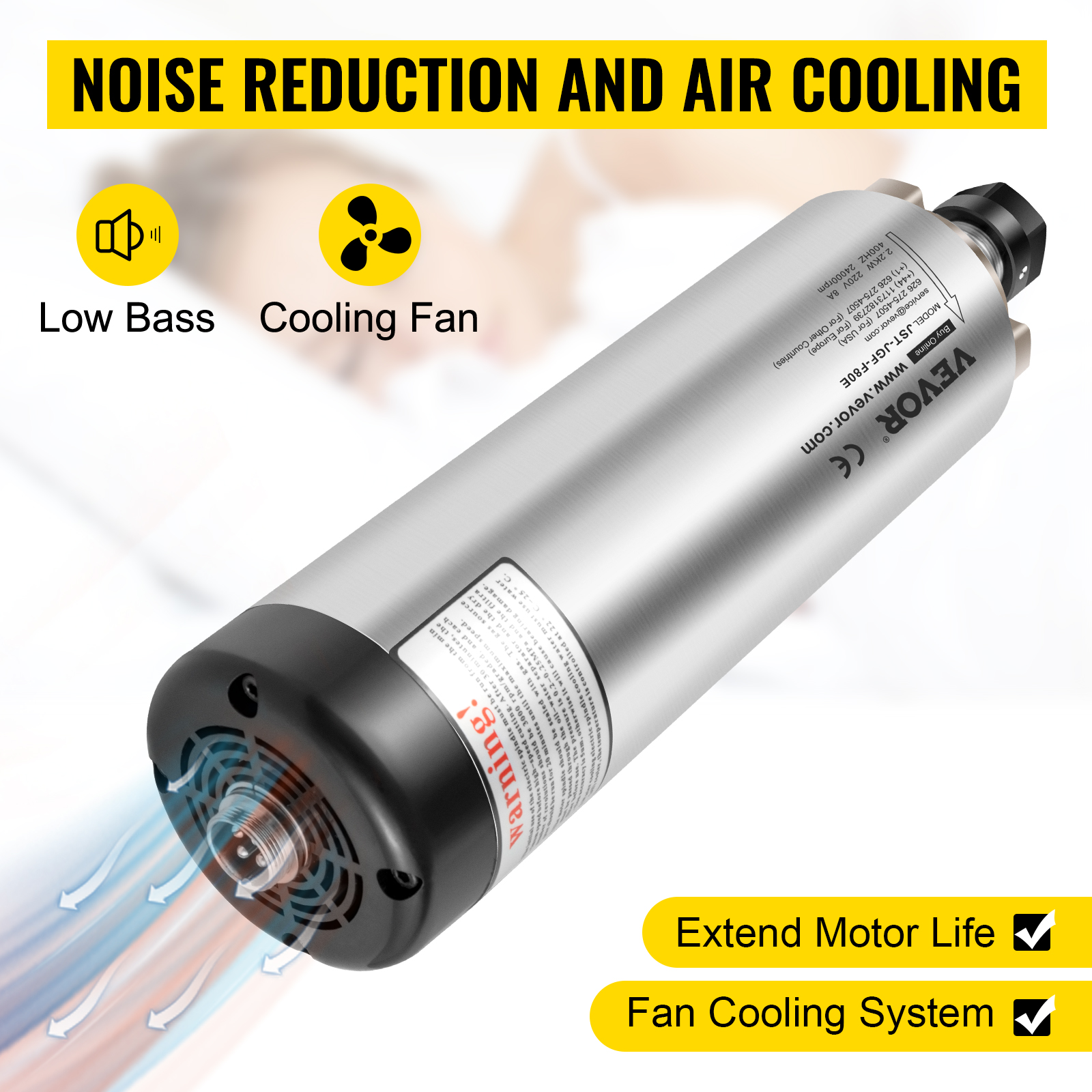

Low Noise & Heat Dissipation: The dynamic balance technology can effectively reduce the noise during use. The scientifically designed air cooling system has a better heat dissipation effect to ensure smooth operation.

-

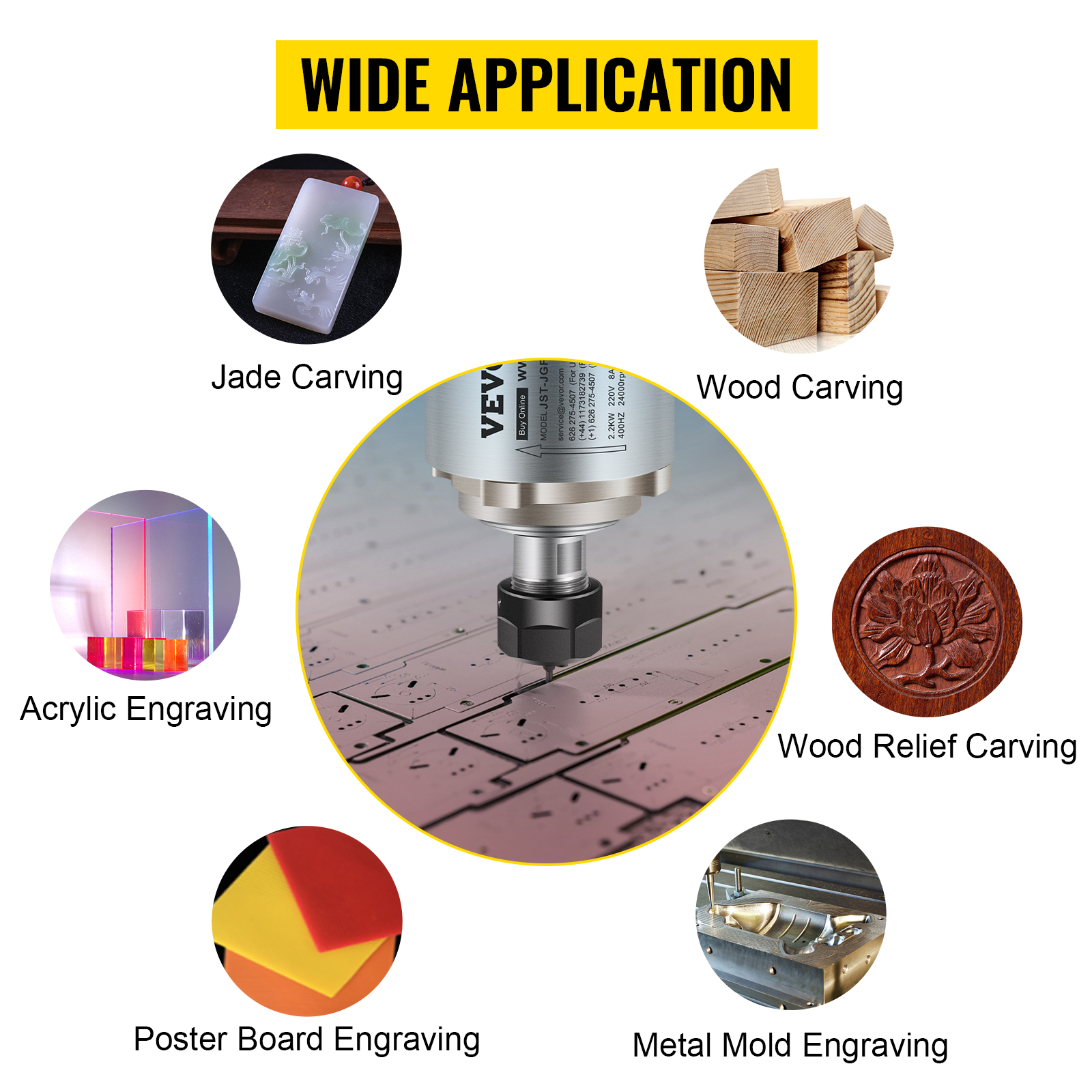

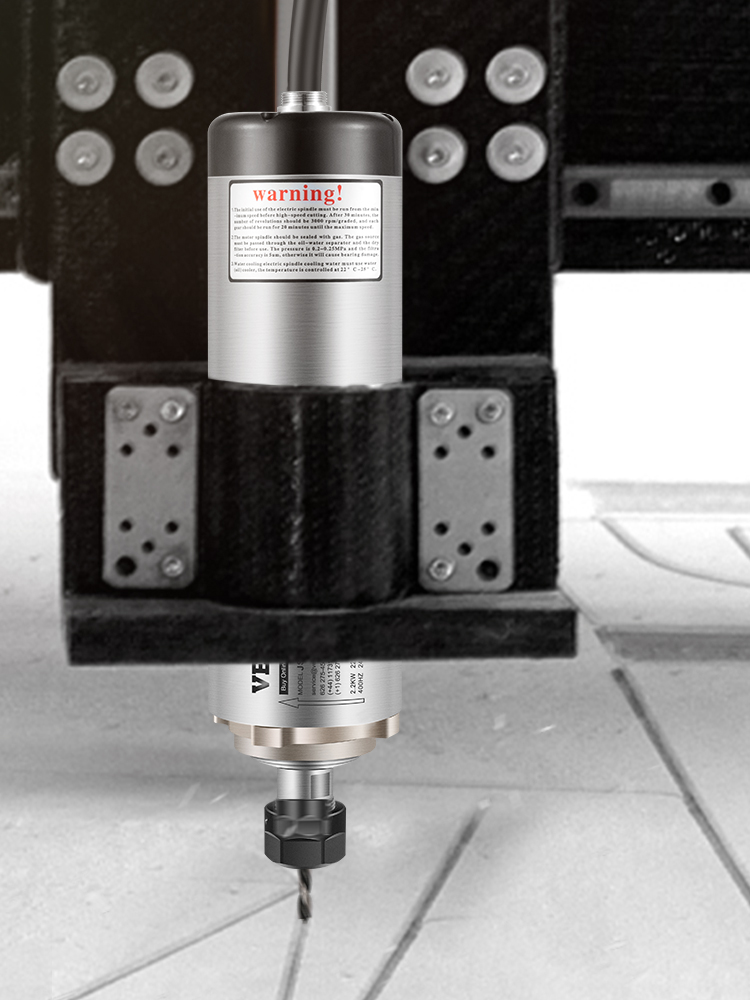

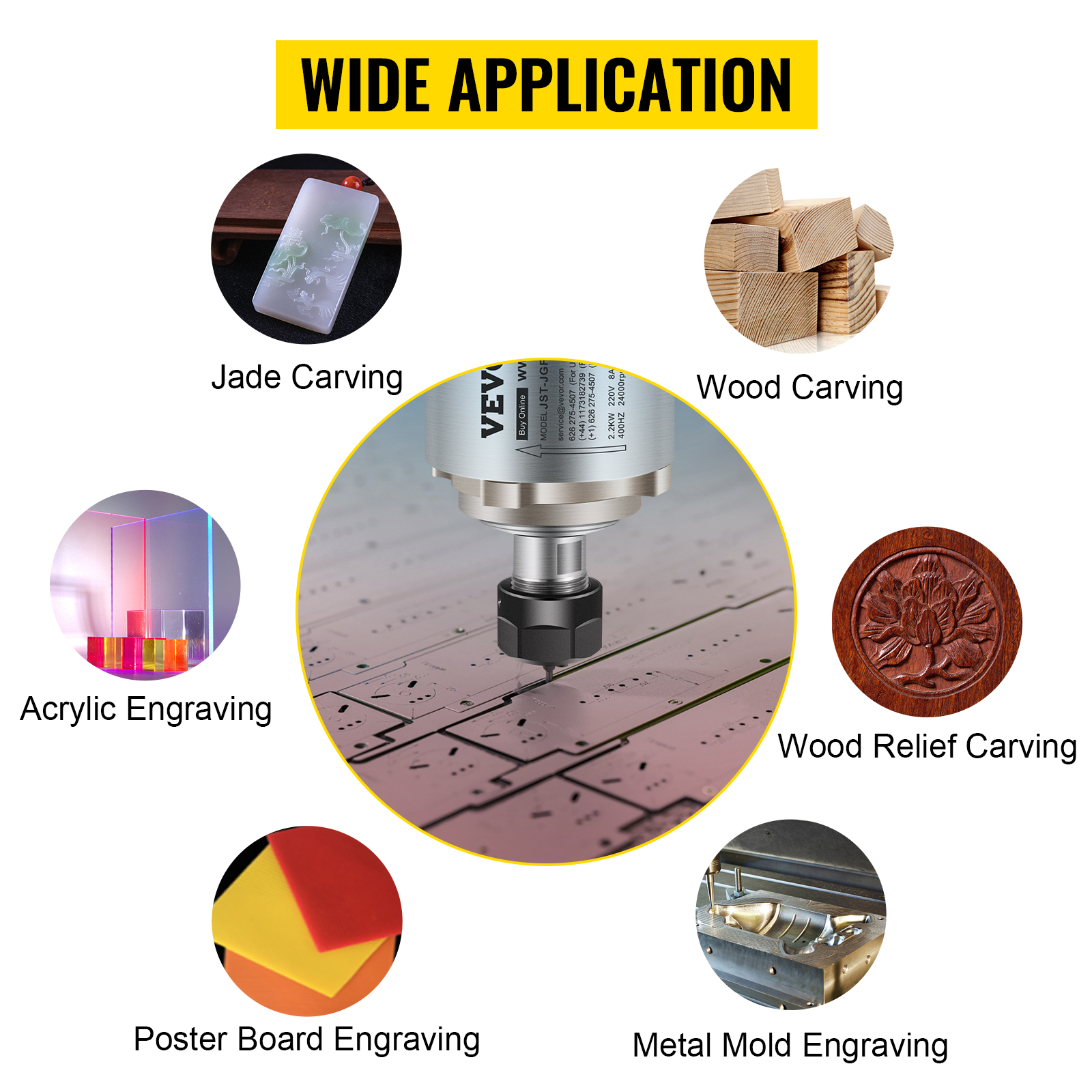

Wide Application: The CNC spindle motor kit is mainly used for engraving machines or frequency converters. It uses air circulation to cool the heat and has a good heat dissipation effect.

SPECIFICATIONS

Brand Name: NoEnName_Null

Origin: Mainland China

Hign-concerned Chemical: None

Certification: CE

Spec(2.2KW): 80 x 215 mm (Diameter: 80 mm x Length: 215 mm)

Power: 2.2 KW

Frequency: 400 Hz

Speed: 0-24000 R/min

Collet Chuck: ER 20

Runout off: less than 0.005 mm

Length: 30 cm (12 Inches)

Width: 25 cm (10 Inches)

Height: 22 cm (9 Inches)

Gross weight: 5 KG(11.02 lbs)

Product: Air Cooled Spindle Motor

-

Technical Parameters

-

ER20 Standard Collet

-

Powerful Bearing

-

Low Noise & Heat Dissipation

-

Premium Tough Quality

-

Incredibly Low Prices

-

Fast & Secure Delivery

-

30-Day Free Returns

-

24/7 Attentive Service

-

Power: 2.2 KW

-

Voltage: 220V

-

Frequency: 200-400 Hz

-

Speed: 12000-24000 R/min

-

Runout off: Less than 0.002 mm

-

Maximum Torque: 1.7NM

-

Product Dimension: 3.1 x 11.8 in / 8 x 29.9 cm

-

Weight: 13.2 lbs / 6 kg

-

1 x Air Cooled Spindle Motor

-

Technical Parameters: Spec: φ3.1 x 11.8 in (Diameter: 8 cm x Length: 29.9 cm); Power: 2.2KW; Voltage: 220V; Current: 8A; Collet Size: ER20; Bearings: 4 bearings; Frequency: 200-400 Hz; Speed: 12000-24000 R/min; Runout off: less than 0.002 mm. Mainly used for engraving machine or used with frequency converter.

-

ER20 Standard Collet: The collet of the CNC router spindle is quenched with manganese steel, and the runout is less than 0.002 mm, which has high precision and is not easy to break the knife, increasing the stability of the working process. Dynamic balance technology can effectively reduce noise during use.

-

Powerful Bearing: The air spindle motor adopts imported bearings with high accuracy, precision, and durability. Significantly improve the hardness and anti-rust performance.

-

Low Noise & Heat Dissipation: The dynamic balance technology can effectively reduce the noise during use. The scientifically designed air cooling system has a better heat dissipation effect to ensure smooth operation.

-

Wide Application: The CNC spindle motor kit is mainly used for engraving machines or frequency converters. It uses air circulation to cool the heat and has a good heat dissipation effect.