SPECIFICATIONS

Brand Name: VEVOR

Hign-concerned Chemical: None

Type: Other

Origin: Mainland China

Hydraulic Pump Type:: Hydraulic Gear Pump

Material of tank:: Metal

Rated speed:: 2850R/Min

Power Source:: 12VDC

Motor power:: 1.6-3KW

Inlet Port Diameter:: SAE6 (9/16'')

Outlet Port Diameter:: SAE6 (9/16'')

Rated Power:: 1.6KW

Flow: 2.0 GPM

Reservoir Capacity:: 4/6/8/10/12/13/15/20 Quart

Function:: Power Up / Gravity Down

Pump Action:: Single Acting

-

Please Note: All of our hydraulic pumps come with an M18*1.5 connector and an additional SAE6 (9/16") connector, which can be replaced according to your actual needs.

-

Product Details

-

Easy to Use

-

Reliable Quality

-

Rapid Start

-

Wide Application

-

Premium Tough Quality

-

Incredibly Low Prices

-

Fast & Secure Delivery

-

30-Day Free Returns

-

24/7 Attentive Service

-

Tank Material: Metal

-

Displacement of hydraulic pump: 0.562-4.350GPM(0.75-5.8ML/R, Applicable to all single power unit for 4, 6, 8, 10 quart)

-

Relief valve pressure: 22 MPA (3200 PSI Max. Relief Setting For Increased Lifting Power on A port)

-

Rated speed: 2850R/MIN

-

Motor power: 1.6KW (Applicable to all single power unit for 4, 6, 8, 10 quart)

-

Motor voltage: DC12V

-

Tank Capacity: 4 Quart

-

Single acting Power-Up/Gravity Down

-

1500 PS Max Relief Setting on B port

-

4 Quart Metal Reservoir

-

SAE # 1 Port, Horizontal mount

-

Hand held pendant with about 15 foot (4.5 m) removal cord and start solenoid

-

1 × 4 Quart Single Acting Hydraulic Pump

-

1 × English Manual

-

Several Related Accessories (Including connectors)

-

Mode: Single-Acting Power-Up/ Gravity-Down

-

Tank Material: Metal

-

Tank Capacity: 6L/ 6Quart/ 1.5 Gal

-

Flow: 2.0 GPM

-

Max. Relief Valve Setting A Port: 3200 PSI

-

Max. Relief Valve Setting B Port: 1500 PSI

-

Rated Speed: 2850R/MIN

-

Voltage: DC12V

-

Power: 1.6KW (Rated), 3.0KW (Max)

-

Duty: 3 Min

-

Traffic: 1.1 cc/r

-

Rotation: Clockwise

-

Connector: SAE # 6

-

Mount Position: Horizontal/ Vertical

-

Control: Solenoid and Handheld Pendant

-

Pendant Control Length: 15ft/ 4.5 m

-

1 x 6 Quart Double Acting Hydraulic Pump

-

1 x English Manual

-

1 x SAE # 6 Connectors

-

Material of tank: Metal

-

Displacement of hydraulic pump: 0.562-4.350GPM

-

Relief valve pressure: 22 MPA (3200 PSI Max. Relief Setting For Increased Lifting Power on A port)

-

Rated speed: 2850R/MIN

-

Motor power: 0.37-5.5KW

-

Motor voltage: DC12V

-

Fuel tank: 8L

-

Single acting Power-Up/ Gravity Down

-

1500 PS Max Relief Setting on B port

-

8 Quart Metal Reservoir

-

SAE # 6 Port, Horizontal mount

-

Hand held pendant with about 15 foot (4.5 m) removal cord and start solenoid

-

1× 8 Quart Single Acting Hydraulic Pump

-

1× Instruction Manual

-

Several Related Accessories (Including Connectors)

-

Model: 10QSAMHP

-

Tank Material: Metal

-

Tank Capacity: 10L/ 10Quart/ 2.5 Gal

-

Flow: 2.0 GPM

-

Max. Relief Valve Setting A Port: 3200 PSI

-

Max. Relief Valve Setting B Port: 1500 PSI

-

Rated Speed: 2850R/MIN

-

Voltage: DC12V

-

Power: 1.6KW (Rated), 3.0KW (Max)

-

Duty: 3 Min

-

Traffic: 1.1 cc/r

-

Rotation: Clockwise

-

Connector: SAE # 6

-

Mount Position: Horizontal/ Vertical

-

Control: Solenoid and Handheld Pendant

-

Pendant Control Length: 15ft/ 4.5 m

-

1 x 10 Quart Double Acting Hydraulic Pump

-

1 x English Manual

-

Several Related Accessories (Including a Connector

-

Material of Tank: Metal

-

Fuel Tank: 20quart

-

Power / Gravity: Single Acting Power-Up/Gravity Down

-

PSI: 3200 PSI Max. Relief Setting For Increased Lifting Power on A port

-

Reservoir: 20 Quart Steel Reservoir

-

Port: SAE # 6 Port, Horizonal mount

-

Hand held pendant with 15 feet(4.5m)removal cord

-

Gross Weight: 34.0 lb (16.4 kg)

-

Package Dimensions (L x W x H): 23.2" x 11.4" x 11.0" (59 x 29 x 28 cm)

-

1 X 20 Quart Single Acting Hydraulic Pump

-

1 X English Manual

-

Several Related Accessories

-

Product Details: Our hydraulic pump is designed with a 12V DC motor (Power: 1.6-3kw) and a 13-quart reservoir. The max relief pressure on A port (SAE#6) is 3200 PSI, and on B port (SAE#6) is 1500 PSI; it is a single-acting pump for power up and gravity down.

-

Easy to Use: This 12V hydraulic power unit has been fully assembled in advance. The wiring is simple and comes with operating instructions. One additional SAE#6 connector and one 15 ft remote control are included in the package.

-

Reliable Quality: The dump trailer pump is made of sturdy metal; thus, the oil tank is not easy to crack or be damaged. As a power unit, this is a perfect replacement pump for remote hydraulic systems. Equipped with an overflow valve, it automatically releases when overpressure, safer and reliable.

-

Rapid Start: With its powerful motor, this hydraulic electric pump is quick to start and quick to output oil; it can provide strong power for hydraulic systems like dump trailers, dump beds and is able to complete lifting in a short time.

-

Wide Application: This power unit is widely used in stackers, small, and medium-sized lifting platforms. It is compatible with many dump trailers and movers and is a direct replacement for 12V DC remotely controlled hydraulic systems.

-

Directions for use:

According to hydraulic principle diagrams, with clean connecting hydraulic powe unit and oil cylinder tubing.

According to the motor and the power of the electromagnetic valve marked characteristics( ac, dc voltage is properly connected.)

Inching motor observe any abnormal phenomenon. In actuators, without load, start the electric, short run test, check whether all the parts run smooothly, determine and correct after loading step by step to normal operation.

Precautions:

The factory production of a hydraulic power unit when leaving the factory, the system pressure has been set. If you want to change, the user according to the actual situation on their own through the knob to adjust the system pressure regualting valve, but no more than nominal pressure of the system.

Carefully check the motor and the electromagnetic valve connection. It is strictly prohibited to pick up.

In the installation and debugging for the first time, we must keep the internal fuel tank oil level, after a work cycle, oil tank should be made up, but not be too full.

Electrical and electromagnetic valve connection should pay special attention to the supply characteristics( ac, dc voltage and has the same sign. Ac power motor shell must be reliable grounding, forbidden ground operation. The motor terminal box note waterproof, moistureproof. Connection for the first time, inching motor check direction, from the motor back end, spin to counterclockwise. Absolutely forbidden motor reverse reverse rotation and oil-free idling.

When the gas tank hydraulic oil must be filtered, filtration precision is not lower than 25 microns.

Power unit can't filter the impurities inside the hydraulic cylinder. So the hydraulic cylinder internal must clean. Lest cause valve failure. Tubing must also be clean.

Maintenance:

We must keep the actuators,and pipeline cleaning,prevent dirt from entering the system.

We must keep the tank oil level,after a work cycle, proper fill oil.Such as pump suction air will cause the damage of pump and the damage of the seal.

100 hours after the running of hydraulic oil for the first time to join,change the new oil.after a year(1500 hours) to replace a new oil.

Working environment temperature high use hydraulic oil of high viscosity,low working environment with low viscosity hydraulic oil.

SPECIFICATIONS

Brand Name: VEVOR

Hign-concerned Chemical: None

Type: Other

Origin: Mainland China

Hydraulic Pump Type:: Hydraulic Gear Pump

Material of tank:: Metal

Rated speed:: 2850R/Min

Power Source:: 12VDC

Motor power:: 1.6-3KW

Inlet Port Diameter:: SAE6 (9/16'')

Outlet Port Diameter:: SAE6 (9/16'')

Rated Power:: 1.6KW

Flow: 2.0 GPM

Reservoir Capacity:: 4/6/8/10/12/13/15/20 Quart

Function:: Power Up / Gravity Down

Pump Action:: Single Acting

-

Please Note: All of our hydraulic pumps come with an M18*1.5 connector and an additional SAE6 (9/16") connector, which can be replaced according to your actual needs.

-

Product Details

-

Easy to Use

-

Reliable Quality

-

Rapid Start

-

Wide Application

-

Premium Tough Quality

-

Incredibly Low Prices

-

Fast & Secure Delivery

-

30-Day Free Returns

-

24/7 Attentive Service

-

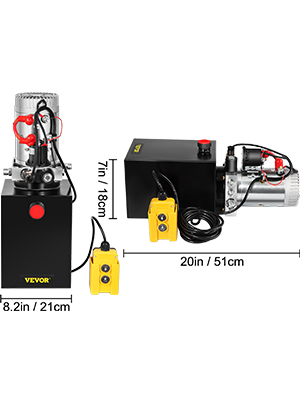

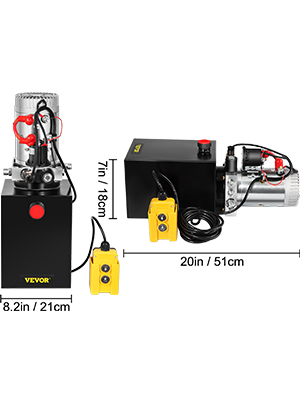

Tank Material: Metal

-

Displacement of hydraulic pump: 0.562-4.350GPM(0.75-5.8ML/R, Applicable to all single power unit for 4, 6, 8, 10 quart)

-

Relief valve pressure: 22 MPA (3200 PSI Max. Relief Setting For Increased Lifting Power on A port)

-

Rated speed: 2850R/MIN

-

Motor power: 1.6KW (Applicable to all single power unit for 4, 6, 8, 10 quart)

-

Motor voltage: DC12V

-

Tank Capacity: 4 Quart

-

Single acting Power-Up/Gravity Down

-

1500 PS Max Relief Setting on B port

-

4 Quart Metal Reservoir

-

SAE # 1 Port, Horizontal mount

-

Hand held pendant with about 15 foot (4.5 m) removal cord and start solenoid

-

1 × 4 Quart Single Acting Hydraulic Pump

-

1 × English Manual

-

Several Related Accessories (Including connectors)

-

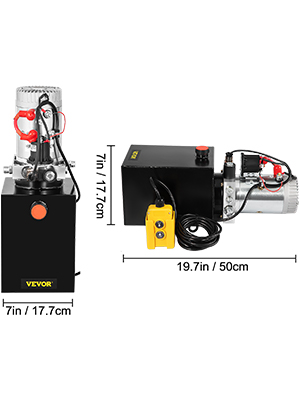

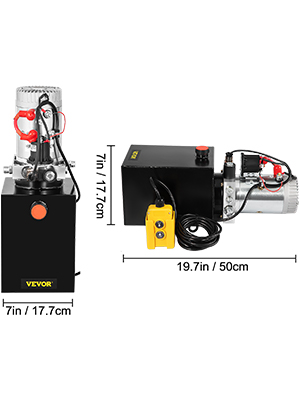

Mode: Single-Acting Power-Up/ Gravity-Down

-

Tank Material: Metal

-

Tank Capacity: 6L/ 6Quart/ 1.5 Gal

-

Flow: 2.0 GPM

-

Max. Relief Valve Setting A Port: 3200 PSI

-

Max. Relief Valve Setting B Port: 1500 PSI

-

Rated Speed: 2850R/MIN

-

Voltage: DC12V

-

Power: 1.6KW (Rated), 3.0KW (Max)

-

Duty: 3 Min

-

Traffic: 1.1 cc/r

-

Rotation: Clockwise

-

Connector: SAE # 6

-

Mount Position: Horizontal/ Vertical

-

Control: Solenoid and Handheld Pendant

-

Pendant Control Length: 15ft/ 4.5 m

-

1 x 6 Quart Double Acting Hydraulic Pump

-

1 x English Manual

-

1 x SAE # 6 Connectors

-

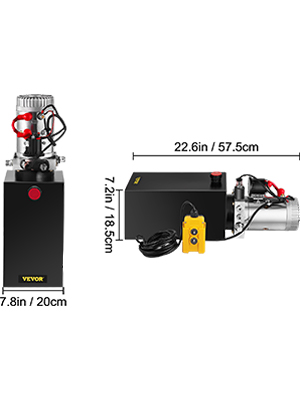

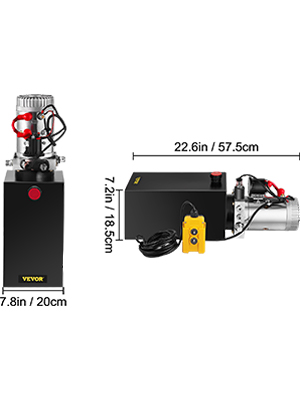

Material of tank: Metal

-

Displacement of hydraulic pump: 0.562-4.350GPM

-

Relief valve pressure: 22 MPA (3200 PSI Max. Relief Setting For Increased Lifting Power on A port)

-

Rated speed: 2850R/MIN

-

Motor power: 0.37-5.5KW

-

Motor voltage: DC12V

-

Fuel tank: 8L

-

Single acting Power-Up/ Gravity Down

-

1500 PS Max Relief Setting on B port

-

8 Quart Metal Reservoir

-

SAE # 6 Port, Horizontal mount

-

Hand held pendant with about 15 foot (4.5 m) removal cord and start solenoid

-

1× 8 Quart Single Acting Hydraulic Pump

-

1× Instruction Manual

-

Several Related Accessories (Including Connectors)

-

Model: 10QSAMHP

-

Tank Material: Metal

-

Tank Capacity: 10L/ 10Quart/ 2.5 Gal

-

Flow: 2.0 GPM

-

Max. Relief Valve Setting A Port: 3200 PSI

-

Max. Relief Valve Setting B Port: 1500 PSI

-

Rated Speed: 2850R/MIN

-

Voltage: DC12V

-

Power: 1.6KW (Rated), 3.0KW (Max)

-

Duty: 3 Min

-

Traffic: 1.1 cc/r

-

Rotation: Clockwise

-

Connector: SAE # 6

-

Mount Position: Horizontal/ Vertical

-

Control: Solenoid and Handheld Pendant

-

Pendant Control Length: 15ft/ 4.5 m

-

1 x 10 Quart Double Acting Hydraulic Pump

-

1 x English Manual

-

Several Related Accessories (Including a Connector

-

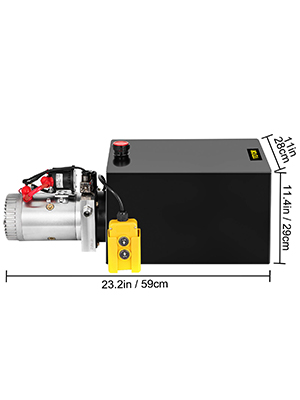

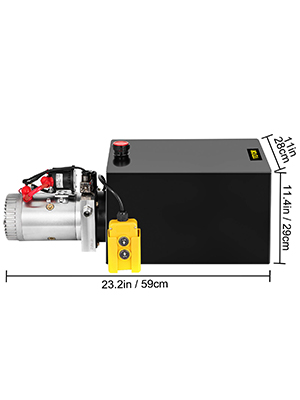

Material of Tank: Metal

-

Fuel Tank: 20quart

-

Power / Gravity: Single Acting Power-Up/Gravity Down

-

PSI: 3200 PSI Max. Relief Setting For Increased Lifting Power on A port

-

Reservoir: 20 Quart Steel Reservoir

-

Port: SAE # 6 Port, Horizonal mount

-

Hand held pendant with 15 feet(4.5m)removal cord

-

Gross Weight: 34.0 lb (16.4 kg)

-

Package Dimensions (L x W x H): 23.2" x 11.4" x 11.0" (59 x 29 x 28 cm)

-

1 X 20 Quart Single Acting Hydraulic Pump

-

1 X English Manual

-

Several Related Accessories

-

Product Details: Our hydraulic pump is designed with a 12V DC motor (Power: 1.6-3kw) and a 13-quart reservoir. The max relief pressure on A port (SAE#6) is 3200 PSI, and on B port (SAE#6) is 1500 PSI; it is a single-acting pump for power up and gravity down.

-

Easy to Use: This 12V hydraulic power unit has been fully assembled in advance. The wiring is simple and comes with operating instructions. One additional SAE#6 connector and one 15 ft remote control are included in the package.

-

Reliable Quality: The dump trailer pump is made of sturdy metal; thus, the oil tank is not easy to crack or be damaged. As a power unit, this is a perfect replacement pump for remote hydraulic systems. Equipped with an overflow valve, it automatically releases when overpressure, safer and reliable.

-

Rapid Start: With its powerful motor, this hydraulic electric pump is quick to start and quick to output oil; it can provide strong power for hydraulic systems like dump trailers, dump beds and is able to complete lifting in a short time.

-

Wide Application: This power unit is widely used in stackers, small, and medium-sized lifting platforms. It is compatible with many dump trailers and movers and is a direct replacement for 12V DC remotely controlled hydraulic systems.

-

Directions for use:

According to hydraulic principle diagrams, with clean connecting hydraulic powe unit and oil cylinder tubing.

According to the motor and the power of the electromagnetic valve marked characteristics( ac, dc voltage is properly connected.)

Inching motor observe any abnormal phenomenon. In actuators, without load, start the electric, short run test, check whether all the parts run smooothly, determine and correct after loading step by step to normal operation.

Precautions:

The factory production of a hydraulic power unit when leaving the factory, the system pressure has been set. If you want to change, the user according to the actual situation on their own through the knob to adjust the system pressure regualting valve, but no more than nominal pressure of the system.

Carefully check the motor and the electromagnetic valve connection. It is strictly prohibited to pick up.

In the installation and debugging for the first time, we must keep the internal fuel tank oil level, after a work cycle, oil tank should be made up, but not be too full.

Electrical and electromagnetic valve connection should pay special attention to the supply characteristics( ac, dc voltage and has the same sign. Ac power motor shell must be reliable grounding, forbidden ground operation. The motor terminal box note waterproof, moistureproof. Connection for the first time, inching motor check direction, from the motor back end, spin to counterclockwise. Absolutely forbidden motor reverse reverse rotation and oil-free idling.

When the gas tank hydraulic oil must be filtered, filtration precision is not lower than 25 microns.

Power unit can't filter the impurities inside the hydraulic cylinder. So the hydraulic cylinder internal must clean. Lest cause valve failure. Tubing must also be clean.

Maintenance:

We must keep the actuators,and pipeline cleaning,prevent dirt from entering the system.

We must keep the tank oil level,after a work cycle, proper fill oil.Such as pump suction air will cause the damage of pump and the damage of the seal.

100 hours after the running of hydraulic oil for the first time to join,change the new oil.after a year(1500 hours) to replace a new oil.

Working environment temperature high use hydraulic oil of high viscosity,low working environment with low viscosity hydraulic oil.